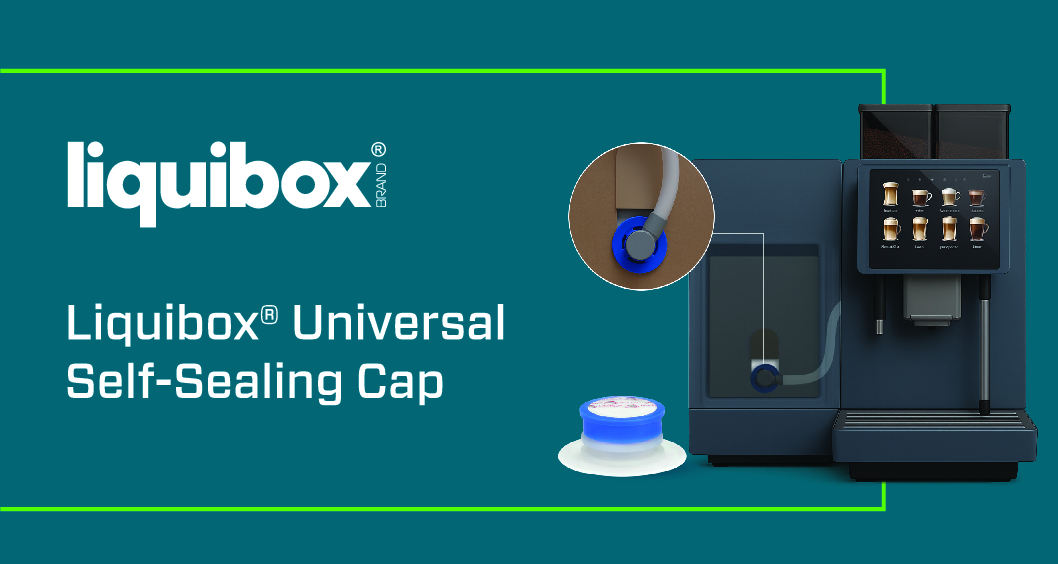

The foodservice industry is embracing a game-changing innovation: the Liquibox® Universal Self-Sealing Cap. Purpose-built for busy environments, this recyclable, self-sealing cap delivers unmatched hygiene, efficiency, and sustainability to milk dispensing.

Solving Foodservice Challenges

Traditional milk containers in coffee machines often lead to spills, leaks, and hygiene concerns. Open-top containers are vulnerable to bacterial contamination, and cleaning them thoroughly is often neglected.

Liquibox®’s cap solves these issues with a sealed bag system. Once empty, the bag is simply disposed of, and the connector is cleaned daily to ensure hygiene.

Key Features & Benefits

- Hygienic Design: The self-sealing system eliminates contamination risks and reduces cleaning needs, keeping milk fresh and equipment safe.

- Fast Changeovers: A plug-and-play design allows quick, mess-free replacements. Just peel, connect, and dispense—saving time during peak hours.

- Universal Fit: Compatible with standard bag-in-box or bag-in-tray dairy systems and most coffee machine connectors, the cap reduces supply chain complexity.

- Sustainable Option: Fully recyclable in existing PE streams, the system significantly cuts CO₂ emissions—by 70% compared to 1L milk cartons and 45% versus HDPE bottles (COMPASS EcoImpact LCA).

Industry-Wide Application

This versatile cap supports automated coffee machines, smoothie stations, and soft serve machines. It adapts to fresh, ESL, hot fill, and aseptic processes while maintaining top-tier performance.

A Future-Proof Solution

The Liquibox® cap reflects a step forward in hygiene and sustainability. By minimizing waste, protecting milk quality, and streamlining operations, it sets new standards in foodservice.

Want to learn more about how this innovative cap can transform your operations? Contact us at http://www.liquibox.com