Fast maintenance and ease of use are part of the product philosophy for IMACH SRL Innovative Packaging Solutions. This is one reason why the Italian machine builder has chosen the Vision adhesive melter from Robatech as a new standard component for industrial hot melt adhesive application.

The offer was already on the table. Everything was clear. Massimo Di Paolo, Technical Manager of machine builder IMACH, would offer their customer, Caffè IZZO, a Concept melter, Enduro heated hoses, and an AX jetting head from Robatech for automated gluing of shipping packages. But Massimo Di Paolo had not expected the call from Marco di Tullio, Area Sales Manager of Robatech Italy.

from Robatech for automated gluing of shipping packages. But Massimo Di Paolo had not expected the call from Marco di Tullio, Area Sales Manager of Robatech Italy.

Virtual World Premiere

“On March 17, 2021, the virtual world premiere of our product innovations was to take place,” Marco di Tullio tells us. “I invited IMACH because I knew that our smart Vision melter and the new Performa heated hose would fit perfectly with the product philosophy of the innovative machine builder.”

Fast Maintenance

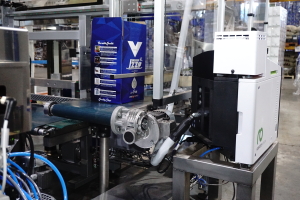

IMACH, a young company based in Sant’ Apollinare in the Italian province of Frosinone, develops and produces customized end-of-line packaging systems. “We put a lot of emphasis on customers being able to service our equipment quickly and operate the entire packaging process easily,” explains IMACH’s Technical Manager. “Of course, this also applies to the adhesive application system,” adds Di Paolo. “When I saw the Vision melter at Robatech’s virtual trade show with the Smart Terminal and the maintenance door that gives access to all maintenance-related components, I immediately asked Robatech for a new offer for the Caffè IZZO project.” Meanwhile, IMACH’s end-of-line packaging system is running at full speed at Caffè IZZO in Anagni, Italy. The line erects shipping cartons with auto-lock bases and top-loads up to 750 coffee capsules per minute into cartons for 50, 100, or 150 coffee capsules. At the end of the line, an AX Diamond jetting head from Robatech intermittently applies two hot melt beads to the two short lid flaps. The long lid flaps are then pressed on briefly. Around 15 secondary packs are glued every minute. They later end up directly on the supermarket shelves.

Clean Adhesive Application, Smart Operation

“Vision is a melter of a new dimension,” Marco di Tullio enthuses,” because it regulates the heating temperature quickly and precisely and ensures a stable delivery pressure.” The Area Sales Manager goes into even more detail: “Together with the fully insulated Performa heated hose, which is connected to Vision and the application head via the practical PrimeConnect plug coupling, we keep the adhesive temperature and thus the adhesive viscosity consistent. In this way, we achieve a uniform and reliable adhesive application.”

Clean and reliable packaging gluing is very important to Viviana Izzo of Gruppo Izzo. “Our customers are used to quality.” As roaster and manufacturer of coffee blends and vending machines, the company has been supplying its products to hotels, bars, and restaurants since 1975. In 2010, the company began to offer coffee for private households. With the production of pods and coffee capsules starting in 2016, the packaging process became more and more time-consuming. “Previously, we had taped the shipping boxes by hand,” says the daughter of Caffè IZZO’s founder, “but then we had to increase productivity in the packaging process.” Looking at Vision’s Smart Terminal, Viviana Izzo adds: “Vision’s modern operating concept suits us very well. Even from a distance, our operators can tell via the colored LEDs whether everything is running smoothly or when adhesive needs to be refilled.”

Outstanding Energy Efficiency

Massimo Di Paolo from IMACH is happy: “The new melter requires 20 % less energy than the previous Concept model. Together with the Performa heated hose, we can now integrate an adhesive application system into our packaging systems that brings significantly more sustainability to the gluing process.” Marco di Tullio laughs: “Who would have thought that Vision would be so convincing at first sight.” Does IMACH know that it was the first Vision sold worldwide?

THE CUSTOMER

IMACH develops and produces customer-specific end-of-line packaging systems in Sant’Apollinare, Italy. The OEM uses the smart Vision melter and the innovative Performa heated hose for automated adhesive application.

CUSTOMER STATEMENT

“We want to make life easier for our customers. The Vision melter and Performa heated hose fit perfectly into our product philosophy: straightforward system integration, smart operation, and fast maintenance of the adhesive application system.”

“We want to make life easier for our customers. The Vision melter and Performa heated hose fit perfectly into our product philosophy: straightforward system integration, smart operation, and fast maintenance of the adhesive application system.”

Massimo Di Paolo

Technical Manager, IMACH SRL Innovative Packaging Solutions